- Newsroom

- Published on:

V4Smart establishes fully digitalized battery cell production with MHP

- One of the most innovative projects in Germany: digital factory at V4Smart in Nördlingen – joint project between V4Smart, MHP, and the Porsche Werkzeugbau Gruppe

- Software-Defined manufacturing (SDM) approach taken with the assistance of technology partners such as SAP, AWS, and Cybus

- Cloud-based digital twin of the entire production operation a key success factor

- SAP S/4HANA Public Cloud used as a central ERP tool for the essential business processes

Ludwigsburg / Nördlingen – V4Smart, the joint venture between Porsche and Varta newly founded in March 2025, decided to set up a fully digitalized production operation from the cloud to mass-produce the first German cylindrical cells for the automotive sector. To this end, the entire IT architecture was set up on the basis of the Software-Defined manufacturing principle in just ten months, before the company was even founded, enabling flexible, software-controlled production processes that can be quickly adapted to new requirements, which in turn increases efficiency and innovation in manufacturing.

Federico Magno, Group CEO at MHP: "The project demonstrates how digital twins elevate production to new levels of innovation, performance, agility, and efficiency. Data availability from the digital factory enables precise, targeted control of the start of production – without compromising quality or speed. It is impressive proof of how partnership-based collaboration in Software-Defined Manufacturing drives excellence with tangible impact."

Greenfield production facility set up within ten months

The starting point was the production line in Nördlingen, which was newly conceived by V4Smart and the Porsche Werkzeugbau Gruppe with the aim of developing and manufacturing high-performance Li-ion cylindrical cells of world-leading quality. The cylindrical cell production facility was developed, built, and installed extremely quickly within the space of a year. This production facility is the first of its kind in Europe to mass-produce cylindrical cells, boasting an output of 80 ppm (parts per minute). The right technical infrastructure behind the production operation thus had to be created quickly – and needed to be highly automated, digital, fast, and adaptable.

Markus Wambach, Group COO at MHP: “Speed was the name of the game in this major joint project. And we were able to make sure of this because we adopted a highly agile approach to the project from the outset in order to come up with the process design and commission the system, enabling us to provide a timing guarantee up to the start of production. Within just ten months, we created a lean, modern, and scalable IT infrastructure for establishing a greenfield production facility.” This short implementation period was also possible because the MES supplied by the Porsche Werkzeugbau Gruppe, which is responsible for controlling the systems, and the interfaces on the MHP side were clearly defined in advance. Data communication always takes place in real time, with no loss of time due to communication between the interfaces.

V4Smart chose MHP as its implementation partner partly on account of its broad portfolio of consulting and implementation services in the field of IT architecture, cloud infrastructure, and digital twin technology, plus its numerous reference projects involving the digitalization of factories using SAP S/4HANA, MES, and other cloud-based approaches. However, the decision was also based on the convincing nature of the agile greenfield concept and the commitment to providing sufficient consultants in the areas of strategy, controlling, process, IT integration, production, commissioning, and ongoing support, says Dr Walter Heibey, Partner at MHP and lead architect of the project.

Dr Walter Heibey goes on to explain: “The consistent implementation of a cloud-only solution significantly helped to accelerate the project. As a result, the Software-Defined manufacturing approach was able to demonstrate the value it adds in a quick and targeted manner. By integrating SAP S/4HANA Public Cloud and SAP DM, the fully digitalized processes needed for production, logistics, and quality have been made available. Using the lakehouse – based on AWS – all data points of each cell were monitored in real time during commissioning to guarantee the quality of the cells.”

Henning Hiebsch, Partner at MHP and Project Lead for V4Smart: “V4Smart stands for innovation, speed, and digital excellence – a flagship project and benchmark for the industry. Within just a few months, we have created a factory that demonstrates how Software-Defined Manufacturing is redefining production. With the digital twin, physics on the shop floor and data beat in perfect synchrony – interconnected, processed in real time, and fully adaptable. This project proves that when technology, flexibility, agility, teamwork, and vision come together, true future is created.”

The Software-Defined manufacturing approach made it possible to implement the company processes within ten weeks, fully integrated with the SAP S/4HANA Public Cloud as the central ERP tool. The focus was on maximum standardization and the use of preconfigured processes.

Lutz Kramer, CEO at V4Smart: “Within a very short space of time, MHP, together with V4Smart and Porsche, was able to improve the data quality to such an extent that a switch to mass production was possible. The throughput rate stands at 80 battery cells per minute. In order to achieve this figure, the monitoring of data quality was automated. The generation of a large quantity of high-quality data within a short period of time allows V4Smart to monitor and manage the manufacturing process in real time and avoid digital waste.”

Just a few weeks after the start of production, V4smart was able to manage its production operation with high-precision data analysis. The production operation for the battery cells fitted in the new Porsche 911 Carrera GTS T-Hybrid was commissioned in record time in April 2025.

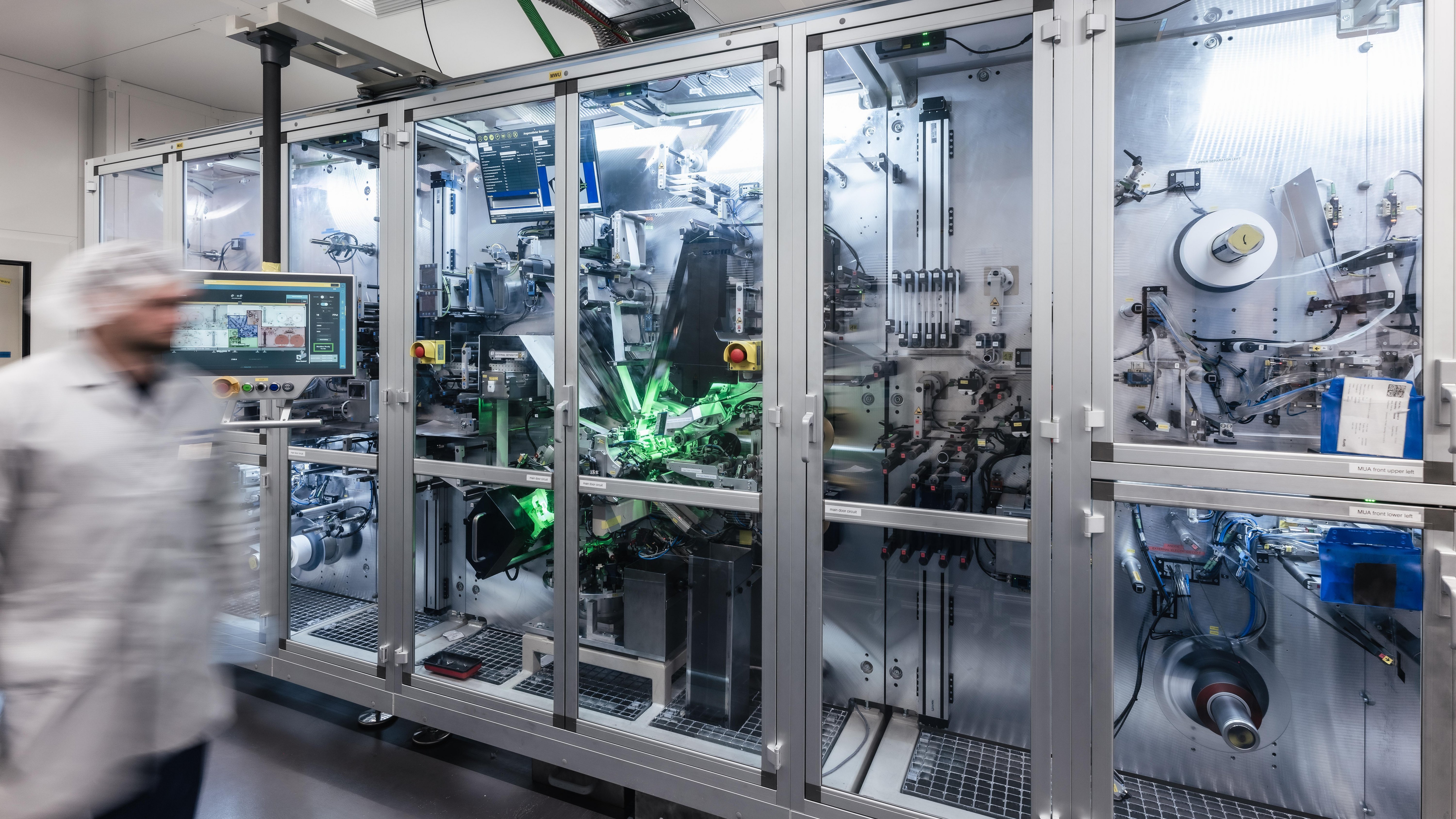

One of the most innovative projects in Germany: digital factory at V4Smart in Nördlingen – joint project between V4Smart, MHP, and the Porsche Werkzeugbau Gruppe. (photo: Porsche AG)

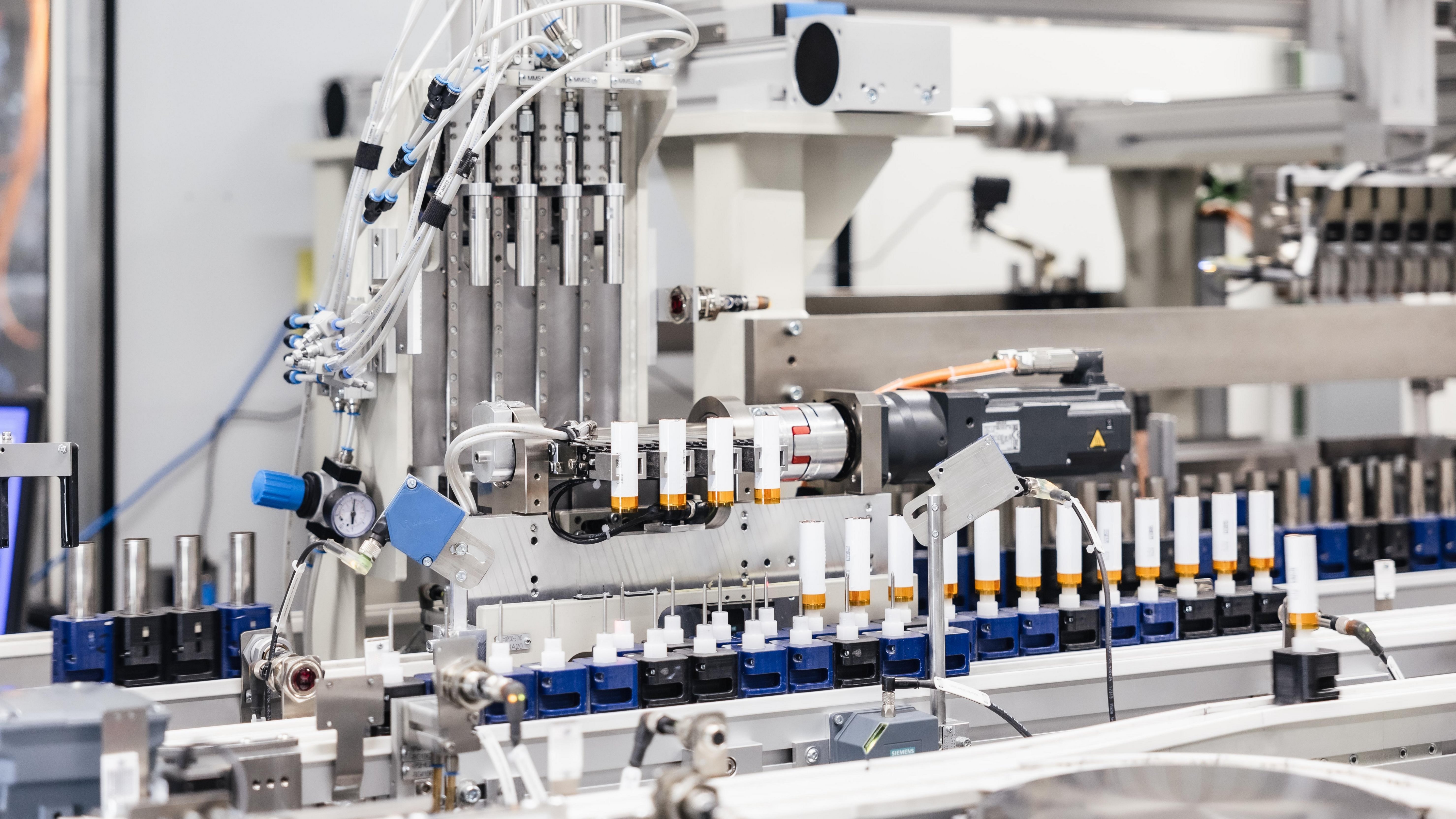

Digital factory at V4Smart in Nördlingen – joint project between V4Smart, MHP, and the Porsche Werkzeugbau (photo: Porsche AG)

(photo: Porsche AG)

(photo: Porsche AG)

(photo: Porsche AG)

Federico Magno, Group CEO of the management and IT consultancy MHP (photo: MHP)

Lutz Kramer, CEO at V4Smart (photo: V4Smart)

Markus Wambach, Group COO of the management and IT consultancy MHP (photo: MHP)

Dr Walter Heibey, Partner at the management and IT consultancy MHP (photo: MHP)

Henning Hiebsch, Partner at the management and IT consultancy MHP (photo: MHP)

MHP Newsroom

Need information about MHP or our services and expertise? We are happy to help and will gladly provide you with current information, background reports, and images.