- Blog, Digital Transformation

- Published on: 25.04.2024

- 14:34 mins

Bridging the LkSG and CSDDD: Key Similarities and Differences in the Path to the EU Supply Chain Act

The enactment of the EU Supply Chain Law is taking shape: On March 15, 2024, the qualified majority of EU member states agreed to the directive. On March 19, 2024, the Legal Affairs Committee of the European Parliament (JURI) approved the political agreement on the directive with 20 votes in favor and 4 votes against (with no abstentions). The next step is the approval of the European Parliament's plenary session before the outcome must be formally confirmed by the European Council.

The aim of the European Supply Chain Directive, commonly known as CSDDD or CS3D (short for “Corporate Sustainability Due Diligence Directive”), is to ensure that the supply chains of relevant companies become more sustainable in the future. It seems natural to compare the European Supply Chain Directive (CSDDD or CS3D) with Germany's Supply Chain Act (Lieferkettensorgfaltspflichtengesetz, short: LkSG), which came into effect in 2023. But are these two directives truly that similar? And to what extent can we view the LkSG as a harbinger and preparatory measure for the CSDDD?

In this article, you’ll learn how your company can navigate the requirements of the LkSG and CSDDD directives, how to avoid possible penalties, and to what extent digital solutions can help you to evaluate your suppliers and implement preventative measures in the right places.

LkSG and CSDDD at a Glance

Both Germany's LkSG and the EU Supply Chain Act aim to enhance sustainability and human rights compliance throughout the value creation chain. In addition, both directives emphasize and specify the due diligence requirements that businesses must uphold.

German Supply Chain Act (LkSG)

- Target group:

German companies with more than 1,000 employees (since January 2024) are affected. - Requirements:

Companies must ensure environmental sustainability and human rights compliance along their supply chain. Potential and actual risks must be identified, documented and minimized using preventive and corrective measures. Liability:

The act does not hold companies directly liable under civil law for damages caused by their suppliers.- Sanctions:

Violations could lead to fines of up to 2% of the global annual turnover and a ban from public tenders for as long as 3 years. In addition, the directive makes it possible for affected parties to file claims against companies for up to five years.

Forthcoming European Supply Chain Directive

- Target group:

Affected are companies with more than 1000 employees and a global net annual turnover of 450 million euros. The CSDDD also applies to non-EU companies if they generate a net turnover of 450 million euros in the EU.

The law will be phased in as follows:

· By 2026 (two years after enactment), companies must have implemented the directive into national law.

· By 2027 (three years after enactment), the directive applies to companies with more than 5,000 employees and over 1.5 billion euros in turnover.

· By 2028 (four years after enactment), the thresholds decrease to 3,000 employees and more than 900 million euros in turnover.

· By 2029 (five years after enactment), in the final step, companies with more than 1,000 employees and over 450 million euros in turnover will be covered.

- Requirements:

Companies must identify human rights and certain environmental risks in their value chains, take preventive and remedial measures, and report on them. Risks must be identified and eliminated. Additionally, companies are required to create a climate plan outlining how they intend to achieve the 1.5-degree goal, contribute to climate neutrality, and set corresponding emission targets. - Liability:

The regulation encompasses the activities of business partners of a company along the entire supply chain. This includes the manufacturing of goods as well as the provision of services. It encompasses product development, raw material extraction, procurement, processing, transportation, delivery, and storage of products or product components. Also, indirect suppliers in the upstream supply chain are covered by the regulation.

Furthermore, some activities of downstream business partners of a company are included in the activity chain. This concerns the distribution, transportation, and storage of products, provided that these activities are carried out by business partners for or on behalf of a company. Downstream indirect business partners are not to be considered in this context. - Sanctions:

The plan is to implement a combination of regulatory control, including fines, and civil liability. The national legislator is expected to set a maximum fine of up to 5% of the company's net annual turnover. Furthermore, the directive introduces civil liability, stating that in the event of cross-border incidents (e.g., if damage occurs in Bangladesh or Pakistan), the law of the EU Member States will apply instead of the law of the foreign location of the damage. This enhances access to civil legal protection for those affected and streamlines procedures.

On December 14th, 2023, the European Council and the European Parliament reached a preliminary agreement. This agreement concerns the duty of due diligence of companies in the area of sustainability. A key aspect of the CSDDD is the requirement for companies to identify and reduce the negative impact they have on human rights and the environment. This duty of care requirement applies along the entire value chain, including upstream and downstream activities. In addition, companies must prepare climate transition plans that set binding targets for the reduction of emissions and that they are realized.

Similarities and Differences Between the Supply Chain Acts

At first glance, the two laws show many similarities and commonalities. This is especially true when it comes to their main goal: Both the LkSG and the CSDDD seek to drive forward the transition to more ethical business practices and sustainable supply chains.

Business activities should be in harmony with both nature and society over the long term; the supply chain must not have a negative effect on human rights or the environment.

In general, sustainability is at the heart of both directives. However, the LkSG focuses primarily on the aspect of human rights, while the current draft of the EU Supply Chain Directive will place additional focus on reducing climate change.

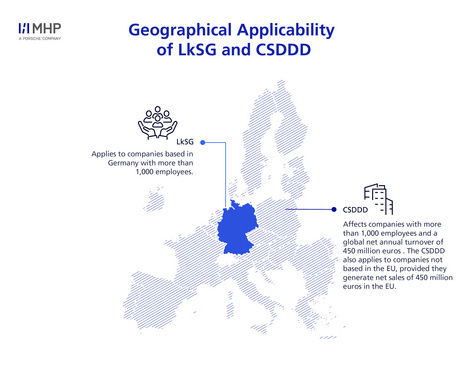

Additionally, the LkSG only affects German businesses and companies that have their head office, principal place of business, or a branch office in Germany. The CS3D, on the other hand, applies to the entire European Union. But aside from their scope and geographical jurisdiction, both laws have some differences:

Concept

- LkSG: Specifies which duty of due diligence must be upheld along the supply chain

- CSDDD: Companies are required to assess their supply chains for environmental impact and human rights violations; the CS3D defines more specific due diligence obligations in this regard than the LkSG.

Substantive basis

- LkSG: Human rights and environmental due diligence

- CSDDD: It contains both human rights and environmental due diligence obligations as well as requirements for a climate plan.

Differentiation between direct and indirect suppliers

- LkSG: Yes

- CSDDD: No, the CSDDD encompasses the entire activity chain, including the activities of downstream business partners.

Possible sanctions

- LkSG: Financial penalties (up to 2% of the annual turnover, depending on the type and severity of the violation), exclusion from public-sector contracts

- CSDDD: A combination of regulatory oversight, including fines, and civil liability. The national legislature shall establish a maximum fine of 5 percent of the annual net turnover, to be applied on a case-by-case basis depending on the circumstances

Size of the affected companies

- LkSG: Larger companies with more than 1,000 employees

- CSDDD: Companies with more than 1,000 employees and a global annual net turnover of 450 million euros fall under the CSDDD. This regulation also applies to non-EU-based companies if they generate a net turnover of 450 million euros within the EU.

Role of stakeholders

- LkSG: Less relevant

- CSDDD: Highly pronounced

Liability

- LkSG: No liability under civil law

- CSDDD: Civil liability for damages along the supply chain.

Overall, it can be stated that the CSDDD imposes stricter requirements and potential legal consequences compared to the LkSG - particularly regarding environmental impacts and climate protection.

What Companies Can Expect When the CSDDD Takes Effect

The provisional agreement, which was reached in December 2023, must now be approved by the European Council and the EU Parliament and adopted in full. As soon as the regulation is subsequently published in the Official Journal, it will enter into force publicly 20 days later. The EU member states then have two years to transpose the directive into national law and adapt laws to the provisions of CS3D.

As the EU Supply Chain Act incorporates parts of the German Supply Chain Act, German companies can expect the corresponding LkSG regulations to be tightened. Once the CS3D comes into force, EU law will take precedence over national law. This means that companies must follow the requirements of the CSDDD – even if they are already acting in accordance with the LkSG. It is therefore important to implement the LkSG with the utmost conscientiousness now, and thus prepare optimally for the stricter regulations of the CSDDD.

Challenges in Complying With the LkSG and CSDDD Regulations

The LkSG is like peeping through a keyhole – a first glimpse at the challenges that companies will be confronted with when the CSDDD takes effect. There are a few pain points associated with the challenges presented by both the German and the EU Supply Chain Acts:

- Documentation and evaluation of supplier information: Companies are required to collect comprehensive information about suppliers and identify potential risks in the supply chain. The challenge here is to ensure transparency across all the various suppliers. Suppliers often do business in different regions and sectors and use a variety of data formats.

- Engagement with a wide variety of suppliers: Because the suppliers typically come from many fields of work and sectors of industry, it can be difficult to engage with them. Language barriers, cultural differences and different business practices can hinder communication and cooperation.

- Continuous monitoring and adjustment: The need for ongoing risk analysis demands that the supply chain be monitored continuously and more rigorously than ever. That means that companies will need to adjust their processes on an ongoing basis. This is the only way for them to react to changing market conditions, new risks or compliance requirements.

- Ensuring implementation on the part of suppliers: Companies are required to ensure that their suppliers adhere to the mandatory standards. This responsibility includes providing necessary support, such as training or workshops. Often, companies will need to invest in training or support to make sure their suppliers can meet these requirements. The company must also recognize its own responsibility and critically evaluate its practices. Ending a partnership with a supplier should always be considered a last resort.

- Implementation of new processes and tools: To improve compliance and risk assessment in their supply chains, businesses should update their operating procedures and make use of digital tools. To that end, they will need to deploy suitable software and tools and ensure that they continuously optimize their processes. This, of course, results in additional IT expenses.

MHP offers businesses a service package designed specifically for LkSG and CSDDD compliance, which includes not only consultation but practical assistance with implementation, as well. With this offer, we hope to make it possible for businesses to effectively implement both current and future measures required by the supply chain directives.

The pain points show: Businesses must master multiple challenges in order to comply with their due diligence obligations. Implementation demands more than just a considerable allocation of resources. A fundamental redesign of supply chain processes and management will also be required to meet the regulatory demands and ensure that standards of ethics and sustainability are met all along the supply chain.

3 Tips for Successfully Meeting Supply Chain Challenges

In the face of the the introduction with the LkSG and the the enforcement of the CSDDD, businesses will be forced to make some changes – but there’s no reason to be discouraged. Meeting the due diligence obligations can have a positive impact on your company’s future viability and profitability; a sustainable supply chain is often more reliable and efficient and reinforces your company’s positive reputation with customers. However, long-term planning and careful attention to the upcoming requirements will be essential.

The following tips will help you implement measures to comply with the LkSG and CSDDD going forward:

1. Take a systematic view of potential hurdles that must be overcome

By launching a coordinated effort to identify stumbling blocks, you will be able to implement appropriate measures early on. This allows you to solve problems before they become major obstacles. By identifying risks early on, it will be possible to introduce preventative measures such as process optimization or strategic adjustments to ensure that things keep running smoothly.

2. Use a structured approach based on the challenges you have identified

A carefully planned approach can help your company to implement efficient processes that are precisely tailored to the risks you have identified. By analyzing and understanding the challenges within the supply chain, you can develop targeted solutions and optimize the cooperation with your suppliers using clear communication and regulated work processes.

3. Establish clear guidelines and standards for the required data

Clear specifications are critical to ensuring the quality and consistency of the information you need. They will minimize potential sources of errors or inaccuracy in the data you collect. With consistent data collection standards, your company can ensure that the data is accurate and reliable. That simplifies risk analysis and monitoring.

Your company should also adopt a holistic perspective that includes both strategic and operative aspects. This means addressing both short-term challenges in your day-to-day business and formulating long-term goals. The task can be made easier using specialized tools and software solutions that are designed for risk analysis, data management and monitoring. This allows you to manage the complexity of your supply chain and simplify compliance with legal regulations.

How MHP Can Assist Your Company in Complying With the Supply Chain Act

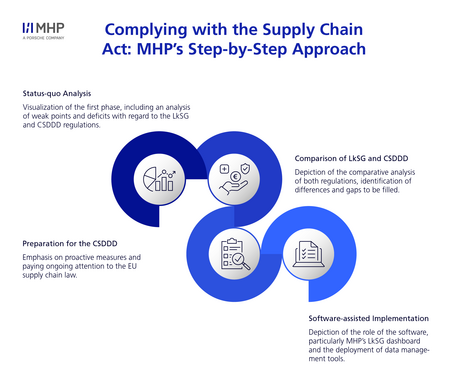

It is becoming ever more important to integrate sustainability into your organization and processes. When it comes to digital solutions, comprehensive advisory services and profound expertise in the LkSG and CSDDD regulations, MHP is a reliable expert and partner. We can help make it easier to implement measures that will help your company comply with the Supply Chain Act and ensure that they are maintained in the long-term. Here's how we proceed:

- Status quo analysis:

In the first step, our experts take a careful look at the current situation within your company and its supply chain. This allows them to identify any weak spots or deficits relating to the directives, which ensures that you have a solid foundation from which to implement CSDDD compliance measures in the future. In addition, the analysis provides a clear picture of the level of sophistication, legal conformity and acceptance of the LkSG act within the company. This insight makes it possible to optimize and improve processes in a targeted manner that ensures the requirements are met. - Comparison of the German LkSG and the EU Supply Chain Act:

As similar as the LkSG and CS3D seem, they are quite different when it comes to the details. A comparative analysis of the two laws serves to identify possible differences and any gaps that will need to be filled as soon as the stricter CSDDD comes into effect instead of the LkSG. This makes it possible to estimate the effort that will be required for implementation and allows your company to prepare effectively for the transition to the EU Supply Chain Act. - Preparation for the EU Supply Chain Act:

By engaging with the draft of the EU Supply Chain Act early on, we enable your company to initiate measures as soon as possible. This approach helps minimize potential risks, and by being proactive, you enhance your competitive advantages as well as the trust of stakeholders and customers.

By paying ongoing attention to the EU Supply Chain Act, we will make it possible for companies to implement compliance measures as early on as possible. This proactive approach will help to minimize any possible risks, ensuring that your company maintains not only its competitive advantage but also the trust of stakeholders and customers. - A software-based approach:

Software plays a critical role in successfully and efficiently meeting complex compliance requirements. MHP's LkSG-Dashboard on the Microsoft Power Platform allows you to save data from a multitude of different suppliers in a clearly organized way. A clear roles and rights concept ensures that all authorized stakeholders have access. This creates transparency throughout the compliance processes, improves clarity about the measures that are implemented and helps to avoid possible damage to a company’s reputation. In addition, it allows processes to be automated, which saves time and resources. To minimize your workload as related to the Supply Chain Act, a technical interface for SAP data management tools can also be made available.

Using the LkSG as a Stepping Stone Towards the CSDDD

The EU Supply Chain Act will impose obligations on more companies than the LkSG. Those companies that are already compliant with the LkSG are on the right track. However, even they cannot avoid extensive adjustments to meet the requirements of the CSDDD. The key success factor lies in the use of modern technologies and data management tools, such as the MHP LkSG Dashboard and SAP Ariba Supplier Risk. With these tools, you can optimize the supplier management process, provide support for stakeholders, and make supplier relationship management more comprehensive and efficient.

Smart use of automation can also help companies save time and money, as well as allow them to make data-driven decisions based on comprehensive supplier information. With the LkSG dashboard from MHP, you will always have an overview of the supply chain and can react more quickly to potential risks. By visualizing the data, you can keep a watchful eye on even the most complex supply chain structures and ensure that your company will master the challenges that come with the LkSG and CSDDD regulations.

Our service and the personalized advice of our expert consultants will help you to design your supply chain more sustainably and efficiently –to prepare your company optimally for the upcoming CSDDD. Let us advise you now.

Frequently Asked Questions Pertaining to the LkSG and CSDDD

Consider the LkSG as the first Quality Gate on the way to compliance with the requirements of the CSDDD. An early assessment of the current supply chain and the implementation of risk management are advisable. Modern technologies and tools for supplier management can help you with this. Additionally, you should continuously inform yourself about the regulations within the framework of the CS3D and prepare your suppliers for existing changes

To act in accordance with the EU Supply Chain Act, your company will need to concentrate on fulfilling its duty of due diligence along the entire supply chain. The goal is to identify, monitor, and minimize potential risks related to human rights violations, environmental and governance standards.

The overlap between the German Supply Chain Act and its EU counterpart is their shared goals of requiring businesses to take responsibility for the entirety of their supply chain and of preventing human rights violations and environmental harm.

A significant effort will be required to consider the activities of all downstream business partners. However, companies that are already compliant with the LkSG will find that the effort is manageable, as most "upstream" business partners and activities are already known. The question of sanctions also differs: while the LkSG does not provide for civil liability, this is anchored in the CSDDD. However, this does not necessarily entail increased effort for the first time.

The LkSG has an indirect effect on SMEs, because they are frequently suppliers in the supply chain of larger businesses that are affected by the law. That means that it is already important for SMEs to meet the standards of the Supply Chain Act. With the enforcement of the CSDDD, some SMEs will be directly and indirectly affected by the planned regulations and should therefore start engaging with the due diligence obligations now.