- Blog , Cloud

- Published on: 16.01.2024

- 8:10 mins

Complaint Management 2.0: From Integrating SupplyOn to a Fully Digital End–to–End Process

In the automotive and manufacturing industries, precision is absolutely crucial. Effective complaint management is the linchpin that distinguishes between losing a customer and enhancing product quality.

The challenge: In complex networks that include suppliers, subcontractors, and end–product manufacturers, where each step depends on the previous one, dealing with complaints can easily become confusing and complicated. Outdated solutions and isolated communication channels frequently result in prolonged processing times and customer frustration.

The solution: The digital transformation of complaint management by integrating business partners into the process using advanced software solutions such as SAP and SupplyOn.

This article explores how seamlessly interconnecting processes and data streams enable not only more efficient complaint processing, but also extracting valuable insights for quality improvements. MHP's AddOn Complaint Management (CCX) deserves special attention, as it originated from developing a standardized interface for sharing complaint data. It was established together with SupplyOn and other partners, and revolutionizes complaint management in the continued development of SAP.

Why Is It so Important to Optimize Complaint Management in the Age of Digitalization?

Optimizing complaint management is of crucial importance in the age of digitalization. Take this practical example as a means of illustration:

Company A manufactures gearboxes; Car Manufacturer B (the client) complains about a faulty gearbox. When analyzing the cause, it turns out that the faulty component in the gearbox comes from Supplier C. Company B must therefore forward the complaint onto Supplier C and, when it comes to relaying the information to the client (Car Manufacturer B), is dependent on information from Supplier C regarding the error, its cause, and its resolution.

This example only covers a three–part value chain but, in reality, a complaints process can involve many more parties than this. As such, it is all the more important to integrate a fully digitalized complaint management system in order to reduce administration and increase customer satisfaction.

From the complaint cockpit to the CCX: The evolution of digital complaints processing

MHP is playing a decisive role in this integration. The SAP–based AddOn Complaint Cockpit was introduced back in 2005/2006 and acts as a bridge between SAP and SupplyOn for supplier integration. It has an adapter that supports the VDA IT standard Quality Data eXchange (QDX adapter) and serves as an interface for communication between suppliers and OEMs. By automating processes, in particular the electronic processing of complaints using the 8D method, the MHP Complaint Cockpit ensures that customer complaints are processed smoothly and that no data is lost.

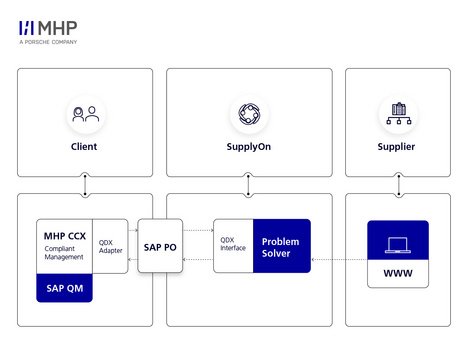

Data from the SAP QM system quality notification is sent to suppliers via the SupplyOn Problem Solver. The SupplyOn Problem Solver facilitates the electronic forwarding of the data to the supplier. The supplier can then structure the complaints and process them in the form of an 8D report. This leads to an increase in customer satisfaction, a reduction in errors, and less administrative work for all employees.

The expansion of the Complaint Cockpit to CCX (Complaint Cockpit eXtension and now Complaint Management) in 2013 was another important step. Working together with other partners made it possible to integrate OEM portals. MHP now provides its own solution for this, paving the way for the complete digitalization of the complaints chain. The expansion of SAP front–end optimization, such as optimized 8D processing, also began in 2013.

The basic prerequisites for the integration of business partners are crucial here. They include known interfaces to business partners’ systems, compatible SCM systems, communication via SAP PO/CPI middleware, and the provision of a QDX IT standard for exchanging quality data. All business partners must have standardized, seamless systems in order to ensure end–to–end digitalization.

The following is an example of supplier integration:

Take Your Complaint Management to the Next Level with MHP and CCX

CCX already offers a wide range of possibilities. Here is an overview:

Mobile fault and message recording

The app simplifies the process of reporting faults and capturing data on mobile devices through a structured, multi–stage approach. Users commence by choosing a reference document (e.g., customer or production orders) and proceed to select specific details or components related to the fault.

They categorize the type of fault from predefined options and specify its exact location, be it in a particular area, on a machine, or elsewhere. Users can provide detailed information about the fault, including a reference quantity, such as the number of faulty items. Additionally, if visual evidence is necessary, they can attach photographs or screenshots.

Integration of damaged part analysis by VDA field

Two inspection lots can be referenced or created directly in the notification for the damaged parts' analysis in order to carry out the damaged parts' analysis by VDA field. The results of this analysis are displayed directly in the quality notification, either in a special tab or in a tree structure on the left–hand side of the user interface. As soon as the analysis results are available in the quality notification, the usage decision can be made directly from the quality notification.

Inspection lot processing via an optional web app

The app streamlines fault reporting and data capturing on mobile devices through a structured, multi–stage process. Users start by selecting a reference document (like customer or production orders) and then proceed to specify fault–related details or components. They categorize the fault type from predefined options and pinpoint its exact location—whether in an area, on a machine, or elsewhere.

Detailed fault information, including a reference quantity like the number of faulty items, can be added. Moreover, users can supplement their reports with visual evidence by attaching photographs or screenshots.

Management of attachments in the notification

Employees and all other parties involved can add attachments, such as images, to a complaint simply by dragging and dropping them. These attachments can then be assigned to specific measures to enable targeted and structured allocation. If the files are images, they are then also displayed in the 8D report. All added attachments are clearly listed in the “Attachments” tab of the respective notification.

Editing window based on 8D logic

Complaints processing follows the established 8D logic, whereby immediate measures play a central role in limiting the immediate effects of a complaint. All relevant documents relating to the complaint can be linked directly in the processing window, including customer orders, delivery receipts, images, and inspection reports.

Attachment management in the 8D report

Attachments can be added directly and conveniently within the 8D report using drag and drop. This makes it possible to easily integrate documents, images, or other relevant files into the report.

Processing the root cause analysis

The root cause analysis includes the Ishikawa analysis (fishbone diagram) to identify and collate possible causes. The identified causes are subjected to an in–depth analysis. The most relevant causes are further analyzed using the 5 Whys technique to determine the root cause of the problem. Cause analysis can also be carried out and documented very intuitively and efficiently using the optional web application.

Mobile 8D processing

The mobile app allows users to edit the 8D report across various devices, providing enhanced flexibility adaptable to diverse work scenarios. Presenting the entire 8D report on a single page simplifies overview and navigation. Additionally, the app includes image management optimization functions and facilitates simultaneous collaborative editing by multiple users, expediting the problem–solving process.

Cost management for complaints

There is a specialized function for recording and categorizing the costs accrued in connection with complaints. Direct recording of costs from the complaints cockpit is available, with flexible billing options. Whether passing on complaint costs internally or externally, there are established billing scenarios to facilitate the structured recording and billing process.

Complaint analysis with Celonis

Using process mining techniques can provide a deep insight into the complaints process and the identification of inefficient steps within this process. MHP has created a standardized data model and a predefined analysis platform to facilitate the evaluation of company KPIs and process conformity. With Celonis, companies can quickly identify where the main problems lie within their complaints process and what steps are needed to resolve these issues.

How Does MHP Support the Integration of Business Partners?

Thanks to many years of experience, MHP is well–versed in integrating business partners. The process spans several stages:

- Set–up phase: This phase encompasses the delivery and basic installation of the MHP AddOn Complaint Management, including the provision of MHP’s best–practice processes. The project is launched and the model of collaboration clarified.

- Get–to–know phase: In this phase, the client's existing complaints processes are analyzed. MHP’s best practices are also presented in order to gain experience with the system at an early stage.

- Adjustment phase: Based on the findings from the previous get–to–know phase, process, or system adjustments are made to ensure the best system support is in place for the client.

- Get–to–work phase: This phase includes end user training and support for the application when it goes live.

With this structured approach, MHP ensures the seamless and efficient integration of business partners.

Work with MHP to Revolutionize the Complaints Process

Efficient and transparent complaints processes involving various stakeholders are pivotal for ensuring customer satisfaction in automotive and manufacturing sectors. The MHP Complaint Cockpit plays a pivotal role here, facilitating seamless communication between companies and their suppliers via SupplyOn integration. An extension of this, the MHP Complaint Management (CCX), further enhances efficiency by involving all stakeholders and streamlining communication across the entire complaints procedure.

This integration offers considerable benefits: It leads to higher component quality, strengthens collaboration through efficient communication, minimizes potential errors, accelerates processes, reduces administrative costs, and significantly increases customer satisfaction.

Contemplating the future underscores the significance of continuing to streamline the complaints process: Increasing digitalization and the integration of business partners means that there are additional opportunities to refine complaints management. Take advantage of these opportunities now and make the most of MHP’s experience and range of solutions!

FAQ

Improving customer satisfaction through complaint management requires faster and more efficient processing. This can be achieved by integrating business partners into the complaints process in order to accelerate communication and increase the quality of the solutions.

SAP and SupplyOn can be integrated into our clients’ complaint management via solutions such as the MHP Complaint Cockpit and its extension CCX. These solutions offer seamless communication between companies, suppliers, and clients.

The benefits of integrating SAP and SupplyOn include greater customer satisfaction, a reduction in errors, faster processes, and less administrative work.

The performance of the integrated systems can be guaranteed through the regular monitoring and analysis of the processes. KPIs (key performance indicators) should be defined to measure the efficiency and quality of complaints processing. Adjustments can be made to further optimize performance where necessary.