- The management and IT consultancy now offers cloud-based SaaS products for making industrial production processes more efficient and data-driven

- These digital products are bundled in the "Industrial Cloud Solutions" cluster ‘

- MHP is initially launching two quality assurance tools: Sounce and paint_it

- Ten teams with a total of 90 developers working in parallel

- At the Porsche plant in Leipzig and at the development centre in Weissach, Sounce has already proven its value in day-to-day operations over the last two years

- ICS is part of Porsche AG’s digital strategy and supports the strategic developments of the Volkswagen Group

- MHP will be presenting ICS and, with Sounce, paint_it and FleetExecuter, a selection of its digital products at the Hannover Messe #HM23 from 17th to 21st April

Ludwigsburg / Hannover – As a technology and business partner, MHP not only guides its clients through the industry’s transformation, the management and IT consultancy itself is also constantly developing. In keeping with its role as a full-service provider for digital transformation, MHP is launching its cloud-based SaaS solutions (software-as-a-service solutions) with immediate effect, together with Amazon Web Services (AWS) as the technology partner and Volkswagen as the industrial partner. These solutions are to make industrial production processes more efficient, data-driven, resilient and sustainable. At MHP, the largest subsidiary of Porsche AG, these services are bundled under the "Industrial Cloud Solutions" (ICS) cluster.

This means that - in addition to existing services – these digital SaaS products will supplement the MHP service portfolio. This is necessary because the production of the future is data-driven and operates largely autonomously. Production networks are highly cross-linked via cloud architectures, enabling fast data exchange. The paint_it, Sounce and FleetExecuter products now expand MHP's business field. Not only are they and all subsequent products based on extensive project experience in cloud strategy, cloud architecture, cloud development and migration, and cloud operations; there are also currently ten teams totalling over 90 developers working in parallel on building these software products

MHP joins the software-based market of the future

Michael Appel, partner at MHP puts it this way: "As part of Industrial Cloud Solutions, we can now supply ready-made digital products that are already OEM-tested, so this will enable us to accompany our customers on their way to developing the production of the future. With ICS, we are combining the expertise of MHP, Porsche and the Volkswagen Group and creating cloud-based Industry 4.0 solutions on the AWS platform. With Sounce and paint_it, the first software-as-a-service solutions are already available, and in the coming years, others will follow”.

Sounce raises the potential for efficiency and cost cutting

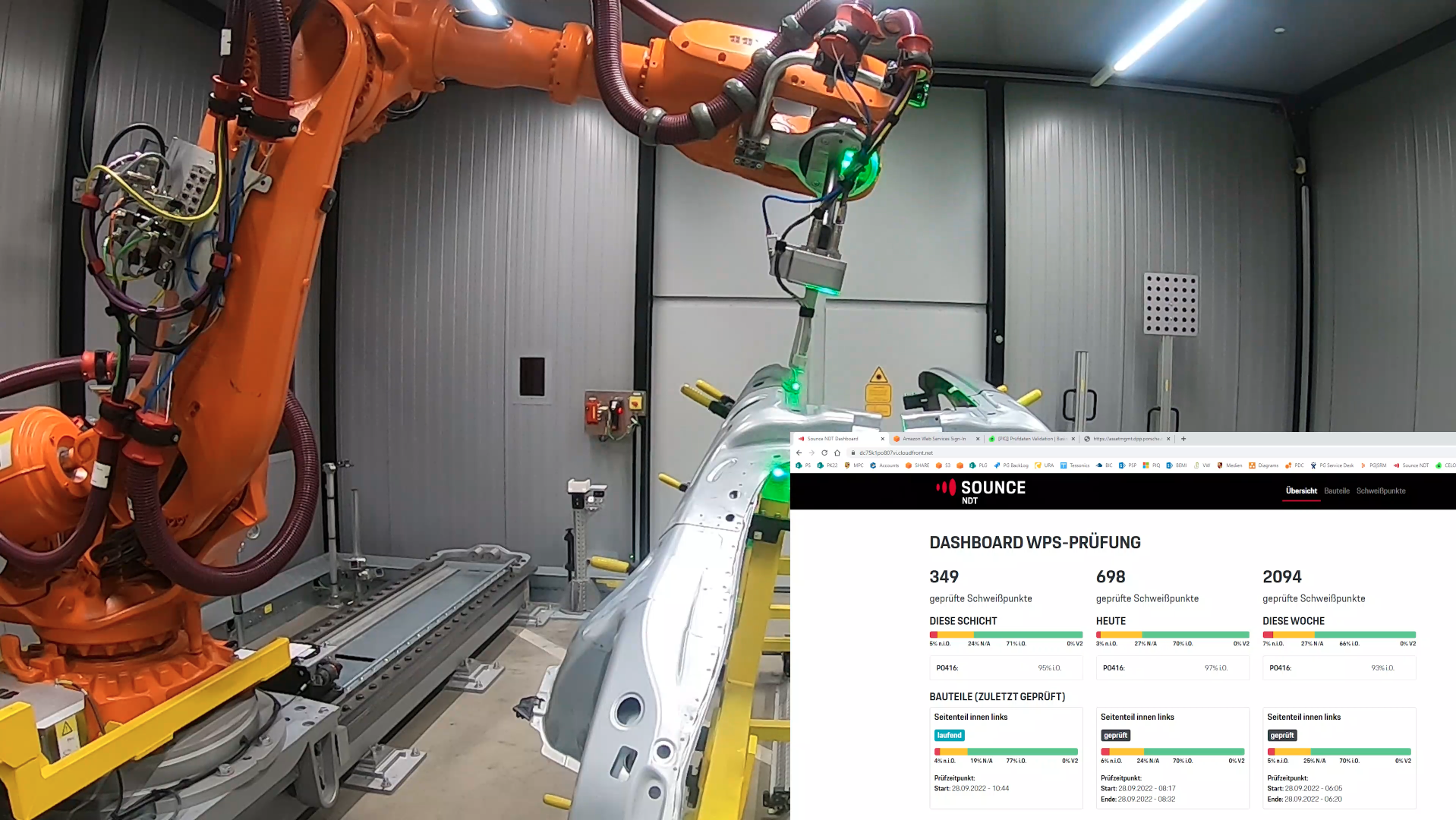

Sounce was developed by MHP in cooperation with Porsche Digital. Porsche has been using the digital quality assurance tool successfully for around two years. As part of the initiation of Industrial Cloud Solutions at MHP, Sounce was integrated into the management and IT consultancy’s product portfolio to develop the product further and establish it in the market. It is an AI-based noise recognition system in near real time.

The system is currently being used at Porsche's development centre in Weissach to evaluate chassis components, and in Leipzig to detect defects and anomalies in car body construction. The parts or components being tested are made to vibrate and generate a characteristic (noise) pattern. If this deviates from the AI’s reference pattern, the system detects a defect and draws attention to it. The seamless monitoring and testing in production reliably detect and document defects that would remain undetected during the usual random quality control at the end-of-line test stand (EoL). At the same time, AI is capable of learning and allows certain tolerances which, in the production of complex components, can never be completely eliminated.

The increase in quality when using Sounce goes hand in hand with a reduction in costs: with a noise detection accuracy of over 96 percent, ten percent can be saved - compared to a conventional testing process.

AI-based quality control for automotive painting with the "paint_it Monitoring System“

The AI-based "paint_it" system offers a hardware-independent solution for determining previously defined quality criteria in an automotive paint shop’s quality assurance system. Among other things, the system can be used to determine information on coating thickness and the paint’s surface quality (orange peel) automatically.

The paint_it monitoring system analyses the collected data and compares it with general, company-specific tolerances and references. The information needed to do this is stored in the cloud and as is the data supplied by the system.

With the help of this SaaS solution, quality defects can not only be detected within a very short time, but to some extent, even predicted. This is because the system recognises trends and uses this ability to predict increasing deviations of individual quality criteria from the permissible tolerance values.

FleetExecuter controls AVGs from all manufacturers

An already well-known and established MHP product, which has now also been integrated into the new business area, is the MHP FleetExecuter. This cloud-based fleet management solution FleetExecuter receives data from the Automated Guided Vehicles and other devices on the shop floor, as well as from downstream systems. It schedules shipments and deliveries on this basis and assigns the transport orders to the AGVs. The software supports the VDA 5050 communication interface.

MHP's new business area - Industrial Cloud Solutions – is based primarily on the comprehensive experience gained from years of IT and management consulting in the automotive and manufacturing sectors. MHP uses the technology and process know-how gained from this experience to offer cloud-based software solutions for engineering, production and supply-chain digitalisation.

MHP at the Hannover Messe

The Hannover Messe #HM23, the world's leading trade fair for industry (from 17th. to 21st. April in Hanover), will be used by around 4,000 companies from the mechanical engineering, electrical and digital industries, as well as from the energy sector, to showcase their technologies and solutions for a networked and climate-neutral industry. The management and IT consultancy MHP is an AWS Platinum Partner and will be represented in Hall 15, Stand D74. The new ICS business area and its products will be presented at the Hannover Messe for the first time at a press roundtable on 18th April.