- Blog, Engineering & Production

- Published on: 19.10.2023

- 10:24 mins

Sustainable Production: Shaping A Better Tomorrow With The Industrial Metaverse

Sustainable production in the automotive industry. How the industrial metaverse improves decision-making & makes production greener.

Can we manufacture cars sustainably? In the era of climate change, carmakers and their production managers are facing a major challenge. Strict EU targets — including a 55% reduction in greenhouse gases across Europe and emissions-free cars by 2035 — are forcing auto manufacturers to set some ambitious goals that will be hard to achieve without changes to the production process. Manufacturers will need to make their processes more sustainable and reduce their products’ carbon footprints in order to comply.

According to Statista, 55% of consumers pay attention to environmental responsibility when choosing a brand. Furthermore, a remarkable 73% of consumers worldwide deem it crucial for the brands they like to take responsibility and embrace sustainable business practices.

Sustainability also plays an important role for consumers when buying a vehicle. According to a forecast by Goldman Sachs, the demand for eco-friendly vehicles will increase significantly and reach a tipping point by 2035, when electric cars will account for half of global car sales. So carmakers who become industry leaders in sustainability would not only be acting in the best interest of society and the planet — they would also gain a clear competitive advantage.

Yet, car manufacturers are not the only ones who will need to act. Suppliers must also become more sustainable. However, more sustainability along the supply chain can increase the cost of the final product. And given the sudden spike in the consumer price index for vehicles, that is not something the market will bear.

The industrial metaverse could be the answer — a way for factory managers and shopfloor managers to meet the need for sustainability without sacrificing profits.

In this article, we will explain the principles of sustainable production using the automotive industry as an example. We will also go into detail on the industrial metaverse — a promising model that uses virtual reality and various metaverse applications to help you design business processes that are more sustainable.

Primary Objectives of Sustainable Production

Sustainable production aims to ensure long-term environmental health using sustainable manufacturing methods. This approach not only minimizes negative impacts on the environment, it also offers social and economic benefits at the same time.

Car manufacturers are on the right path. Since 2006, European carmakers have already reduced their production-related CO2 emissions by 46%. But there is much more to be done.

It will take digital, data-driven approaches to make car production truly sustainable. These types of approaches could include things like:

- digital planning and simulations of processes or factories,

- creating virtual twins,

- integrating artificial intelligence (AI) into production processes,

- or using robotic automation.

Are you interested in improving production processes in your business with approaches like virtual twins, robotics, etc.? Take advantage of our extensive experience with use cases at other companies. MHP is an experienced, professional consulting services provider you can trust.

These cutting-edge approaches can help production managers, managers and decision-makers design processes that are more sustainable. This technology-backed approach enables the design of environmentally responsible production processes and practices. It also aims to conserve resources, reduce emissions, and consider social responsibility.

The EU has passed a range of policies and initiatives to encourage sustainable production and consumption. These include:

- the Eco-management and Audit Scheme (EMAS) — a tool that helps organizations evaluate and improve their environmental performance, as well as

- the Circular Economy and Action Plan (CEAP), which aims to accelerate implementation of the changes required by the European Green Deal while minimizing the impact on people and businesses.

In addition, the Automotive Regions Alliance was formed to ensure a “fair and just transition” of the automotive and supply industry to climate-neutral standards. It is composed of 20 regions from seven Member States and is open to any new region that wishes to join.

Prospects across the Product Life Cycle

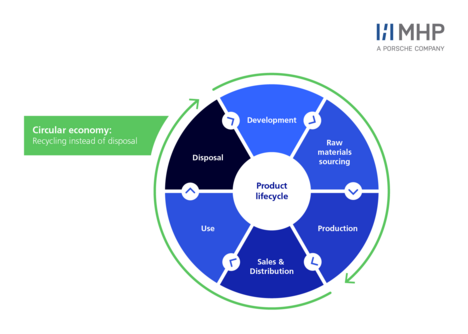

The core concept behind sustainable production is the circular economy. In this approach, resources are reused in a closed loop, which reduces waste while ensuring a steady flow of materials and products in the market.

Don’t throw it away — recycle it for another day. This approach helps make the product life cycle more efficient and sustainable. For example, car parts could be reused, while car engines could be refurbished and given a second life.

Factors that impact a product’s carbon footprint

Procurement and processing of raw materials are responsible for a particularly large proportion of emissions, largely because raw materials processing is often complex and energy-intensive. But disposal also has a massive impact on a product’s carbon footprint. Greenhouse gases are emitted when products are transported to processing plants or disposal sites, as well as when products are melted, shredded, or treated with chemicals during the waste processing.

Smart technologies and automation can conserve valuable resources

Reusing and recycling materials can make a real difference in terms of sustainability — especially when combined with additional measures over the course of the product lifecycle.

For example, simulations can be used to make products "greener", even in the development stage. They can also help businesses make manufacturing and sales processes more climate-friendly. Smart technologies and automation can be especially helpful in car manufacturing as they optimize processes by enhancing efficiency, minimizing errors and conserving resources. In addition, using renewable energy improves the carbon footprint of automobiles at every stage of the product life cycle.

How sustainable production benefits the automotive industry

For car manufacturers, sustainable production offers many long-term benefits. It may require a seemingly large up-front investment, but the enormous savings in terms of energy and raw material consumption means that the costs will be recouped over time. This is where Industry 4.0 technologies come into play.

Under certain circumstances, your company may be eligible for funding from initiatives such as the EU LIFE fund or the Innovation Fund (IF) — and have the potential to become a role model and pioneer in the automotive industry. This would also be good for your brand’s public image — which, given consumer’s increasing demand for sustainable products, would be a competitive advantage.

Most of all, though, sustainable production benefits the environment and climate, and that makes it the cornerstone of our collective efforts to meet Europe’s climate goals.

Industry 4.0 – digital technology for sustainable production

With the help of smart technologies such as edge computing, Industry 4.0 — a.k.a. networked industry — could become “green industry”. As the deadline for the EU target of reducing greenhouse gas emissions by 55% by 2030 approaches, the automotive industry’s hopes are pinned on digital technologies such as:

- Augmented reality (AR): This technology augments our visual reality by superimposing virtual elements on the real world. This lets us see digital information, cars, or visual instructions overlaid on the physical environment.

- Virtual twins: These are virtual representations of physical objects or systems that are continuously updated by real-time data and sensors. They make it possible to monitor, analyze and optimize vehicles or manufacturing processes in a virtual environment.

- Virtual design: Virtual design refers to the use of computer-aided tools and technologies to create and simulate car models in a digital environment. They make it possible to test different scenarios virtually, detect errors early on and avoid costly real-world design iterations.

- Smart contracts: Smart contracts are automated contracts based on blockchain technology. They track transactions and agreements digitally and programmably. This enables the negotiation, execution, and verification of contracts without intermediaries, while simultaneously enhancing the security, transparency, and efficiency of contract execution.

How MHP can help your business become more sustainable

Is one of your goals to make your company's production processes more sustainable? Would you like to enjoy the many benefits that sustainable manufacturing has to offer? As a leading company in the fields of management and IT consulting, MHP is the perfect choice to offer support and guidance during your transition to sustainable production. We can also help you navigate the growing industrial metaverse market, ensuring that you stay competitive and up-to-date with the latest technologies and trends.

We will work closely with you to develop improved management and IT structures that will help your business thrive in a sustainable economy. With their extensive experience with the Industrial IoT, our experts can design tailored solutions for your company and help you integrate industrial metaverse technologies into your production processes.

The cutting-edge technologies used in the industrial metaverse make it possible to fully immerse yourself in a virtual world where your machines, factories and processes are simulated in real time. This digital representations provide you with valuable insights, allowing you to successfully identify weak points, improve efficiency and make your production processes more sustainable.

As a consultancy, MHP can guide you through the process of optimizing your production with a variety of individual consulting services.

On the path to sustainable production with MHP’s consultancy services

- Position your company as a driver of innovation: Become a pioneer in sustainability and optimized production. By developing a clear strategy and suitable approach, you can strengthen your reputation and establish yourself as a driving force in your industry.

- Implementing the industrial metaverse: Our experts will guide you through the process of implementing the industrial metaverse and integrating it into your business processes. We help you select the right technologies, adapt your systems, and train your employees to take full advantage of the potential it has to offer.

- Data for decision-makers: We provide you with well-founded suggestions to help management make value-added strategic decisions. To do this, we analyze your data, identify various possible approaches, and give you clear recommendations for making your production processes more sustainable and efficient in the future.

- Employee education and training: Our consultants will provide your employees with the support they need to successfully transition to the new production processes. We provide education and training that help employees understand sustainable production processes and build the skills they need to work with the new technology.

Reaching climate targets with the industrial metaverse

On the path to sustainable production, the industrial metaverse is a particularly important concept for automotive manufacturers and manufacturing companies.

It brings together digital tools like AR, virtual twins and more, making it possible to optimize production processes before they are implemented in the factory. You’ll be able to see a detailed depiction and analysis of the entire production line, which lets you pinpoint hidden weaknesses and effectively evaluate processes that were previously invisible. With this information, you’ll be able to effectively reduce emissions.

A simulation of the virtual production line can take specific parameters — such as the conditions on-site — into account. In this way, risks and potentials in the production process can be identified at an early stage and addressed before the actual start of production. That kind of optimization helps manufacturers reduce costs, improve efficiency and implement targeted sustainability strategies.

In addition, the industrial metaverse gives all key decision-makers and managers — not just the engineers — direct access to information about the production process, without long lines of communication. This helps them to make immediate, data-driven decisions that improve sustainability and drive CO₂ reduction.

This makes the industrial metaverse the cornerstone of sustainable car production, helping manufacturers optimize their production processes, achieve climate targets and contribute to a more sustainable future.

The benefits of the industrial metaverse at a glance

With the industrial metaverse, your company can:

- Gather data early on and use it to your advantage

- Positively influence sustainability reporting before production begins

- Identify factors that cause increased CO2 emissions

- Recognize where emissions can be reduced and which processes can be optimized

- Precisely track energy and resource consumption

- Identify and test compensation options

- Improve efficiency along the supply chain

- Assess the influence of external factors such as the weather

Overall, the industrial metaverse improves transparency, allowing car producers and other manufacturers to make well-founded, more sustainable decisions.

Let our expert consultants show you how the industrial metaverse can help your business

Sustainability isn’t a matter of will, but of feasibility. And that’s exactly why the industrial metaverse, with its multitude of applications, is as important as it is groundbreaking. It can enhance the sustainability of products throughout their entire life cycle and increase the future-proofing of car manufacturers and other companies. The industrial metaverse can be used to take a holistic approach to improving sustainability, which will permanently reduce greenhouse gas emissions.

Great tasks need great solutions: MHP provides you with custom-tailored strategies across all stages of production — from development and design to manufacturing and recycling. For example, we can assist you in implementing efficient energy management systems and using renewable energies.

Would you like to improve sustainability throughout the production process and reduce your products’ carbon footprint? Then please contact us. Our consultants would be happy to discuss with you what potential the industrial metaverse offers for your company.

FAQ: The industrial metaverse and sustainable production

The circular economy is an economic model that aims to minimize resource consumption, waste and environmental impact. In contrast with the traditional linear economic model, where products are disposed of at the end of their service life, the circular economy strives to increase products’ life cycles, reuse resources and reduce waste. It is based on the three R’s: reduce, reuse, and recycle. These principles ensure that products and materials are used as efficiently as possible.

When a product has a sustainable life cycle, its usage life is extended, the product and materials can be reused, and recycling and conscious consumption are encouraged. All these things support the circular economy. Closed material loops, as well as products that are more durable, reparable, and recyclable, help to reduce the volume of waste and improve resource efficiency.

The industrial metaverse describes the concept of a virtual world that mirrors and simulates real-world machines, factories, buildings, cities, networks and transportation systems. The technology makes it possible to create a persistent, immersive and photorealistic virtual environment in which a large number of people and assets can interact simultaneously. As a result, the industrial metaverse lets businesses virtually implement sustainability strategies and verify their effectiveness using virtual twins, just to name one example.

The industrial metaverse helps make production processes more sustainable by allowing businesses to virtually implement sustainability measures. By creating virtual twins and using real-time monitoring, they can identify potential bottlenecks and see where processes can be optimized before implementing them. Simulating CO2 emissions and reductions and analyzing resource consumption helps companies effectively minimize waste production and improve resource efficiency. The industrial metaverse also provides a platform for developing and implementing sustainable production strategies.