- Newsroom

- Veröffentlicht am:

MHP supports ADMARES on its path to industrialized building production

- MHP, ADMARES, Porsche Consulting, EDAG Group, and Siemens Digital Industries Software are revolutionizing house construction through automated series production

- Management and IT consultancy MHP brings digital ecosystem expertise to industrial building production

- The goal is to create modular, industrially manufactured buildings for residential use worldwide

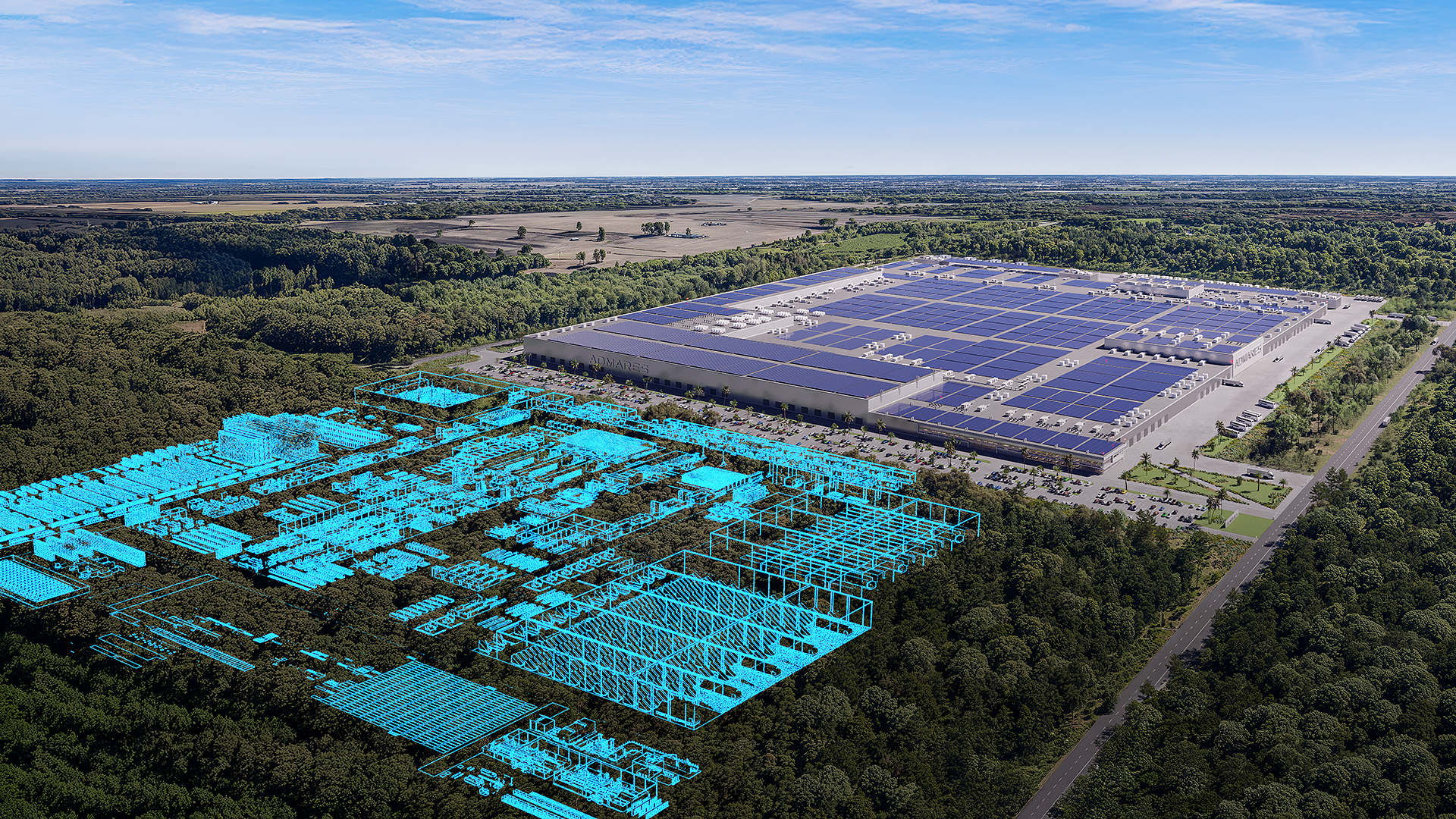

Ludwigsburg/Turku – There is currently no global concept for cost-efficient, high-volume industrialized construction. ADMARES is addressing this challenge with a radically new approach: The company is moving away from predominantly site-based, conventional construction methods and moving residential building production into a highly industrialized smart factory environment. Together with management and IT consultancy MHP, Porsche Consulting, EDAG Group, and Siemens Digital Industries Software, ADMARES has developed a digital manufacturing system that produces modular buildings faster, more cost-efficiently, and more flexibly. The 310,000 m² manufacturing facility is expected to produce up to 16,320 smart homes per year – equivalent to more than 50 units per working day.

“The building modules leave the factory fully equipped and ready to move into,” says Maximilian Sander, Partner at MHP and responsible for the project. “The entire process is designed, configured, simulated, and optimized virtually using digital twins – from product design to delivery.”

Strategic consulting provides direction and certainty

MHP has supported ADMARES as a strategic partner since the early stages: from developing the overarching operational and IT strategy and defining the target digital architecture to evaluating and prioritizing the necessary digitalization steps. The initial focus was on management consulting: Which digitalization concepts enable scaling? What digital capabilities does ADMARES need in the long term? How can the concept be turned into a robust investment model?

This strategic groundwork laid the foundation for all further steps and has created transparency, clarity, and investment security – even before operational solutions are implemented. Only on this basis do MHP and its partners begin designing specific technology solutions, from product lifecycle management (PLM) and manufacturing IT to digital services for the buildings themselves.

A key result of this collaboration is an overall digital ecosystem that through IT architecture intelligently links design, simulation, configuration, and operations. Changes to product variants are automatically incorporated into the simulation model, thereby increasing planning reliability. The integration of digital tools also enables a consistent data structure and a high degree of automation.

Since ADMARES started from scratch, it was able to rethink its first smart factory production processes from the ground up – and do so completely digitally. Even before the first machine was installed, the company designed and calculated the entire production process virtually, from the workflows to the layouts. The result: 30% less initial investment, less than 90% minimum system availability necessary, and a highly flexible manufacturing design.

Automotive expertise for house construction

ADMARES is thus transferring proven principles from the automotive industry directly to house construction: standardized processes, digital planning, automated manufacturing. “Together with ADMARES and our partners, we are shaping an end-to-end digital value chain – from strategic positioning and IT architecture through to a scalable smart factory,” explains Federico Magno, Group CEO at MHP. “The project demonstrates how we combine technological expertise with deep industry and business understanding, transferring our automotive and manufacturing excellence into new industries. The result is a new level of industrial performance in residential construction – faster, more precise, and more cost-efficient.”

While concepts such as modular platforms, just-in-time delivery, and digital twins have already been applied internationally in parts of the construction industry, ADMARES distinguishes itself through the fully end-to-end digital value chain, the high level of automation, and the depth of its vertically integrated production model. Together with MHP and other industry partners, a scalable model for the industrial series production of living space is being created: efficient, precise, and ready to move in.

Together with management and IT consultancy MHP, Porsche Consulting, EDAG Group, and Siemens Digital Industries Software, ADMARES has developed a digital manufacturing system that produces modular buildings faster, more cost-efficiently, and more flexibly. (photo: Admares)

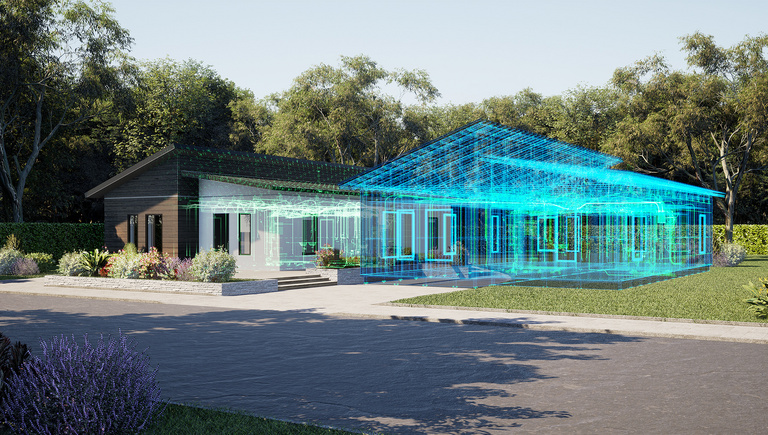

ADMARES Single Family Smart Home (photo: Admares)

ADMARES Single Family Smart Home (photo: Admares)

ADMARES Terrace Homes (photo: Admares)

ADMARES Single Family Smart Home, Interior (photo: Admares)

ADMARES Single Family Smart Home, Interior (photo: Admares)

ADMARES Smart Factory Digital Twin (photo: Admares)

MHP Newsroom

Sie benötigen Informationen zu MHP oder zu unseren Leistungen und Kompetenzen? Gerne unterstützen wir Sie mit aktuellen Informationen, Hintergrundberichten und Bildern.